Decoration & Secondary

Inpres offers a wide range of finishing and post-mold services to help you deliver a complete, production-ready part. Whether you're enhancing aesthetics, adding functional components, or consolidating operations, our decoration and assembly capabilities are built to save time and reduce costs without compromising quality.

From precision-applied labels to advanced in-mold decoration and secondary assembly, we tailor finishing solutions to your product's needs — and integrate them seamlessly into your production process.

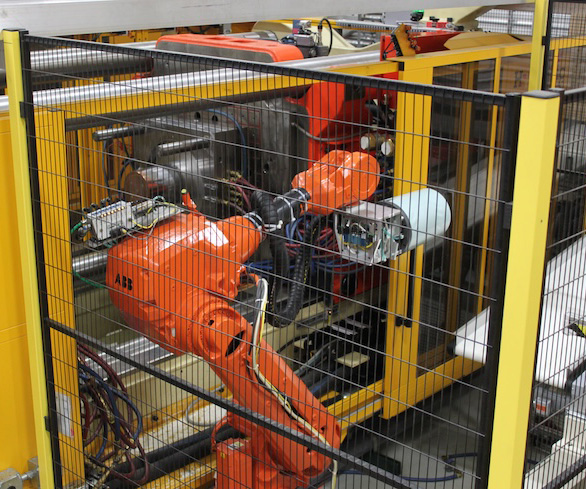

In-Mold Decoration (IMD)

IMD allows for multi-color graphics, textures, and branding to be applied during the molding process itself — reducing secondary steps and enhancing durability. We use both linear and six-axis robots to apply one-sided, multi-panel, and full-wrap labels across a wide range of product sizes and shapes. The result: long-lasting, cost-effective decoration with maximum design flexibility.

Secondary Assembly

We offer a variety of post-mold assembly services to complete your part or subassembly. Capabilities include spin welding, ultrasonic welding, media blasting, induction liner insertion, and cut foam gasket application. Our team works with you to identify the right process and integrate it into your production flow efficiently.

Decoration

We can apply decorative finishes using either your equipment or ours. Options include hot stamping, heat transfer, pressure-sensitive labeling, and additional post-mold branding applications — all tailored to your product's material, form, and market requirements.

Why It Matters

Finishing isn’t just about aesthetics — it’s about delivering a complete product that’s ready for your end user. By handling decoration and assembly in-house, Inpres helps reduce handoffs, shorten timelines, and ensure consistent quality from mold to market.